Kinetic Metallization: IVD Field Repair

Al-Trans® Characteristics

High Corrosion Resistance

High Conductivity

High Adhesion Strength

Metallurgical Bonds

Fully Dense

Self-Healing Abrasion Resistance

Al-Trans® vs. Aluminum IVD

Field Repairable

No Hydrogen Embrittlement

Self-Healing Abrasion Resistance

Reduced Oxidation

Reduced Thermal Distortion

Increased Corrosion Resistance

Lower Cost

Aluminum Repairs with Al-Trans®

Aluminum Ion Vapor Deposition (IVD) is the current standard for replacing cadmium coatings on military aircraft due to its corrosion resistance. However, IVD coatings cannot be repaired in the field, creating maintenance challenges. To address this limitation, the Navy Air Warfare Center at Patuxent River, MD awarded Inovati a Small Business Innovation Research (SBIR) contract to develop a field-deployable, environmentally compliant method for aluminum coating repair.

Inovati’s solution is Al-Trans® 10-20-50, an advanced aluminum-based composite powder engineered for superior corrosion protection. Applied using our handheld Kinetic Metallization™ spray gun, this technology delivers precision coating capabilities without the need for bulky or hazardous equipment.

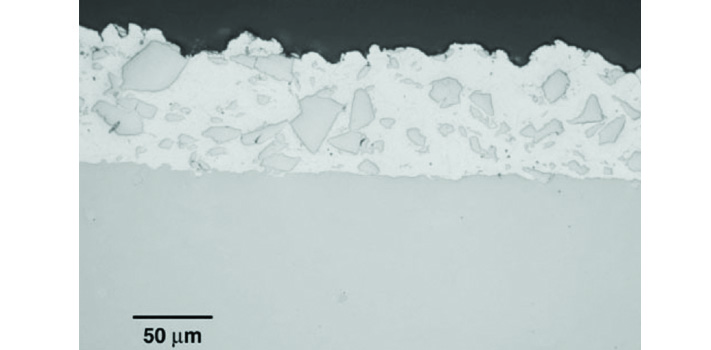

Unlike IVD, molten salt plating, or Alumiplate processes, the KM process offers a simpler, safer, and more versatile alternative. The coating forms a strong metallurgical bond with the substrate, providing exceptional durability. Its near-zero porosity allows it to withstand over 5000 hours of ASTM D1654-92 salt spray and SO₂ exposure, making it suitable as both a repair coating and a primary protective layer for critical components.