Kinetic Metallization: Dimensional Restoration Repairs

KM Dimensional Restoration

Fast Repairs

Low Cost

Superior Properties to OEM

Microns to Inches Thick

Example Applications

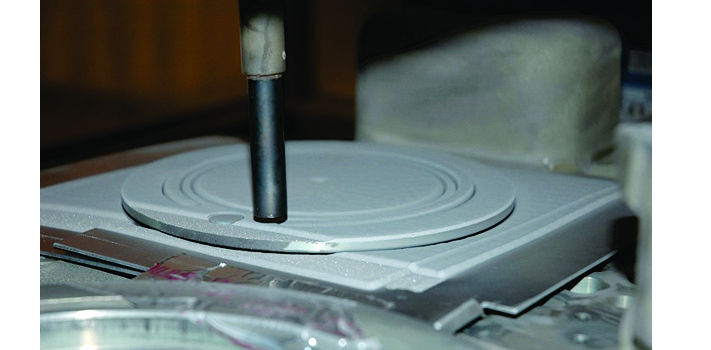

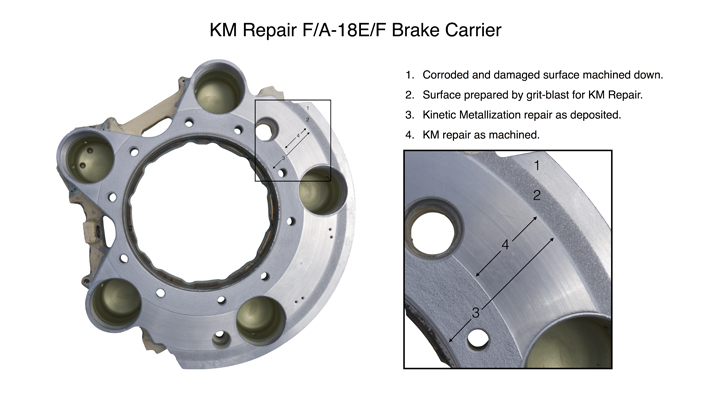

If a component is subject to wear or corrosion damage, it will eventually fall below dimensional tolerances and have to be replaced. Dimensional restoration is a repair technique for restoring components to their original dimensions by depositing new material. Kinetic Metallization™ (KM) is the optimal process for repairing aluminum, magnesium, and steel components. This generally occurs in four steps that are illustrated below.

KM dimensional restorations are performed at very low temperatures and can repair parts that traditional thermal spray processes cannot, like thin walled or heat sensitive components. Low temperatures mean that oxidation and thermal degradation are not a concern for KM repairs, so KM repairs are consistently high quality. Also, all KM dimensional restoration repairs achieve high density with excellent adhesion to the base material. These properties make KM the optimal process for repairing castings.

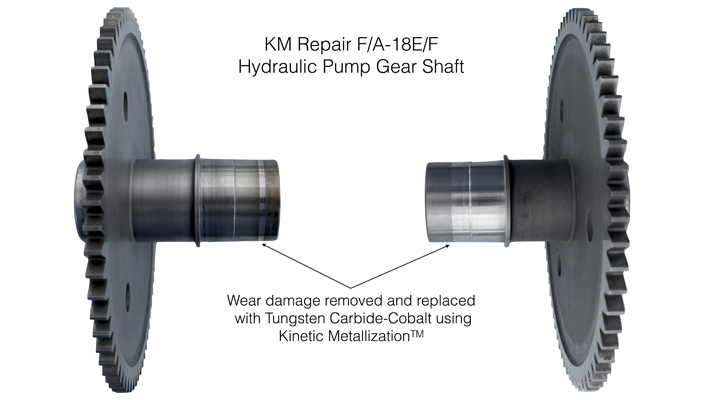

Many KM dimensional repair materials are also protective like KM coatings. It is advantageous to improve the performance of the component while it is being repaired. If corrosion damage is being replaced, it makes sense to repair the damage with a corrosion resistant material, this will increase the lifespan of the component and decrease the need for repairs in the future. For example, the F/A-18 gearshaft repaired with WC-Co is more wear reisistant than the original steel shaft.

Al-Trans® KM coatings are ideal for dimensional restoration repairs on aluminum and magnesium alloy components.

HF 10-10 (WC-Co) is used for dimensional restoration of parts, especially shafts, requiring superior wear resistance.

Ni-Trans™ KM coatings are great for repairing steels and a wide variety of nickel based superalloys.